Quantum Life University, India

In May-June 2019, Quantum Life University built a new dormitory for about 600 training participants at their campus near Vikarabad.

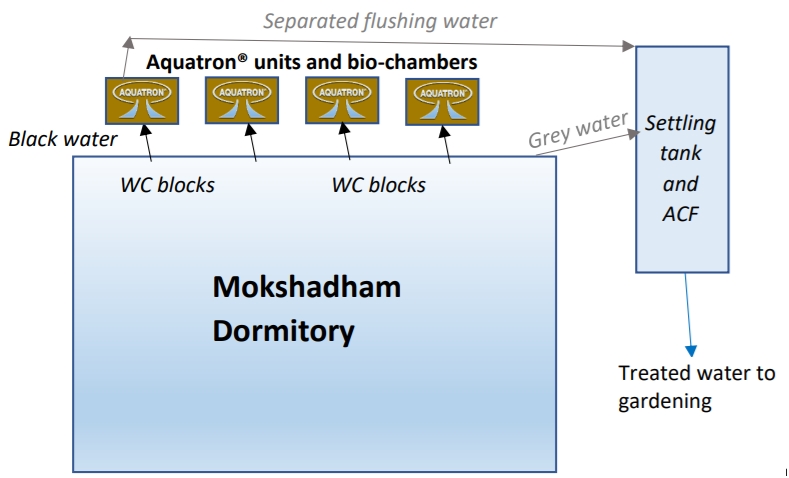

Since the campus is deep in the countryside in a water shortage area, it was essential to have proper onsite sewage treatment that would yield all wastewater back for reuse. A conventional STP was not an option due to the heavy power consumption and other maintenance requirements that would get difficult to manage in a remote location. Furthermore, a conventional system would require a constant sludge volume which is impossible to maintain when there are gaps between training courses. Instead, the University decided to go for a sustainable STP based on Aquatron®, which separates faecal matter from flushing water for natural composting and allows separated flushing water and grey water to be treated easily through basic filters, in this case an activated carbon filter. The system yields back 95% of the water with minimal operating cost.

The new dormitory building has 48 toilets which were connected to four Aquatron® units at the back of the building. The daily water consumption is 80 KLD when courses are on. This includes WCs, showers, laundry and handwash. The purpose of the Aquatron based system is to treat the wastewater with minimal power consumption and maintenance up to a gardening standard. The system was commissioned on June 19th 2019.

The dormitory building was under construction when Aquatron® was integrated in the plan and it was a straight-forward process to implement the required design.

All the 48 toilets are situated on one side of the building and there was suitable space for the Aquatron units and bio-chambers right behind the toilet clusters. The settling tank could be placed nearby too. The bio-chambers for faecal solids were given generous dimensions and the need to empty any composted faecal matter will be almost non-existent as the usage is intermittent.

The settling tank capacity is 80,000 liters and it is used to collect all grey water as well as separated water

from Aquatron.

Execution

The project execution had two parts: Tank construction and plumbing work. Since Quantum Life University had their civil and plumbing team onsite, the entire STP setup including tanks and installation of equipment was completed within two weeks. The bio-chambers were constructed with fly-ash bricks and waterproof plastering was applied.

Bio-chamber structures being built behind the dormitory

Bio-chamber top view with Aquatron® and inspection manholes

Settling tank being built. Bio-chambers visible at the back.

Settling tank completed and Aquatron® units protected with metal sheets.

Simple water treatment plant at Quantum Life University

COSTS

The total cost to the client for the 80 KLD plant came up to approximately Rs 15 lakhs, out of which Rs 7 lakhs was civil work and plumbing and Rs 8 lakhs was for the equipment. The civil work included 4 composting chambers of 2000-3000 liters as well as an 80,000-liter settling tank.

The CAPEX cost for the entire project is less than 50% of the cost of conventional STP equipment for a similar site. Conventional STPs require much larger tanks for aeration as well as for collection of sludge and treated water, which imply a high cost of civil work.

The monthly operating cost for the Aquatron®-based system is a current bill of about Rs 2000 which is primarily for operating one pump from the settling tank through the filters into the fields. This is a fraction of the cost of operating a conventional STP and less than 7% of the Rs 30,000 cost the University would have to incur in 10 days for calling a tanker to empty the septic tanks regularly.

SUMMARY

The Aquatron®-based sewage treatment system at Quantum Life University was ordered in May 2019 and commissioned on June 19th 2019 in order to reclaim 80 KLD of sewage water for instant reuse in gardening. The Aquatron® separator removes the need to treat faecal solids or sludge by separating them from wastewater for direct, natural decomposition. Hence, the entire wastewater (separated flushing water and grey water) can be settled in a 80 KL tank and pumped through an ACF directly into the garden instead of a much heavier conventional STP setup or having to call septic tankers for frequent emptying of septic tanks. The decomposition of faecal matter has been as expected and the filtration process has yielded the required water quality.

The project took about 2 weeks to complete as there was an onsite civil works and plumbing team. Both the capital expenditure as well as operational expenditure were lower than for a regular STP: the system cost about Rs 15 lakhs including all equipment, labour and the construction of a combined tank capacity of more than 80,000 liters. The monthly operating cost for the Aquatron®-based system is about Rs 2000 which is just about as cost-effective as it can get. Based on their experience with the system, Quantum Life University are going to convert even more buildings in their campus into Aquatron®-based sewage treatment.