The Moonstone Project, Aquatron 4×300

The Moonstone Project: “To design and build Britain’s leading autonomous Eco-house”. Leigh och John Croft built their Eco house east of Sheltenham. This house has nine toilets connected to their Aquatron system. The toilet most far from the separator is 50 meters away.

To be the best Eco house in the Country, innovative and often untried technologies had to be used in its construction.

The whole building now has levels of insulation 65% better than the very Best German Eco standard of the Passiv Haus—U values of the walls of 0.06 w/m2K cf. 0.15 w/m2K.

Full commercial quarrying equipment was brought in to excavate and process all 12,000 tonnes of Cotswold stone material on site. All this material was recycled in the battered wall construction or for hardcore for the driveways. The only building waste removed from site was in three 8 cubic yard skips.

A Canadian ICF (Insulated Concrete Formwork) was used with water proof concrete—to provide a water proof underground basement and water proof tanking to a third of the building which was underground. Large Hanson 200mm and 300mm thick 7m long x 1.2m wide floor panels had to be craned into position.

Highly insulated triple glazed windows with a U value = 0.7 w/m2K were imported from Germany

Walls were constructed with a 1m thick Cotswold stone battered wall with a 3 degree pitch with super insulation of 400mm of extruded polystyrene to totally fill the cavities. All ground floors were built on 300mm of heavy duty insulation. The inner wall was treated with a epoxy tanking materials and the full height of the walls dressed with a 4mm neoprene jacket to create an air and water tight structure.

Eight bore holes and a further 1 1 /2 miles of 40mm pipe was buried around the property t o provide heating to the 12Kw Ground source heat pump.

A 44 square metre arrangement of flat plate solar thermal panels provide the house with 85% of its hot water and heating requirements.

All drinking and other water requirements are met by an on site spring

Rain water is collected from the roofs and discharged via pipe work hidden in the walls and used to fill reflection and infinity pools at the extremities of the building

A two tier vertical reed bed was constructed to process all waste water on site—to drinking quality standard.

An Aquatron worm biogester unit composts all solid wastes from toilets and waste food and is then re-used as compost

The house was the first domestic property in the UK to use Rehau Earth pipes installed 3 metres below ground. Via this pipe work incoming air is ducted through 6 lengths of 50m underground Earth pipes pre-warming the air in the winter months and cooling it in the summer months.

A full mechanical heat recovery system, filters and purifies all incoming air into the property and recovers wasted heat from the kitchen, bathrooms, tumble dryer and Aquatron bio-gester.

The house is illuminated with LED lighting saving an additional 60% over normal energy efficient lighting.A CLIPSAL lighting and automation system was fitted into the house, with PIR’s switching lights on and off when necessary and all lighting circuits are set on timers with occupancy detection to save further electricity.

A Schluter super thin 25mm screed underfloor heating system, provides rapid heating comparable with traditional radiators and traditional underfloor systems. The very thin Supa flow liquid screed only needs an input temperature of 35 degrees to reach a room temperature of 21 degrees, making it perfect for the small Ground source heat pump.

Two 1500 litre stratified hot water thermal storage cylinders have multiple inputs allowing for easily connection of solar thermal, ground source heat pumps and other renewable energies.

The 3000 litre hot water storage covers the house for approximately 7 days, with any short fall being met by the Ground source heat pump.

Thought you lovely people at Aquatron may be interested in my short video: fifteen years after we first installed Aquatron:

Reed Beds

I won’t pretend to know how all this works, or that I have any knowledge, suffice to say get an expert – and you wouldn’t do too badly if you get the country’s leading expert who designed our system, Dr Rick Hudson of Cress Water www.cresswater.co.uk. The design has to be just right, there are as many different types of sand as you will find in a souvenir shop on the Isle of Wight. We constructed to the exact specification that Rick gave us. This is a two tier, two stage vertical reed bed that in essence filters all our black and grey dirty water from washing machines, dishwashers, toilets, showers and baths to pure drinking water ready for discharge back to the water course or for recycling back to our own drinking supply – all without any complicated media or electricity – just Mother Nature.

Read more here how reed beds work and see an interesting film from the property.

Highly recommend that you visit the website which has an incredible amount of information about the whole project.

www.themoonstoneproject.co.uk

Info

More images

Aquatron 4x300 in the basemant,. An Aquatron unit composts all solid wastes from toilets and waste food and is then re-used as compost

Aquatron 4x300 in the basemant,. An Aquatron unit composts all solid wastes from toilets and waste food and is then re-used as compost

A two tier vertical reed bed was constructed to process all waste water on site—to drinking quality standard.

A two tier vertical reed bed was constructed to process all waste water on site—to drinking quality standard.

44 square metres of TiSun flat plate solar collectors, provide 3000 litres of hot water storage to two innovative stratified Proclean water tanks. From early March to mid-November 2009, all hot water came from these panels

44 square metres of TiSun flat plate solar collectors, provide 3000 litres of hot water storage to two innovative stratified Proclean water tanks. From early March to mid-November 2009, all hot water came from these panels

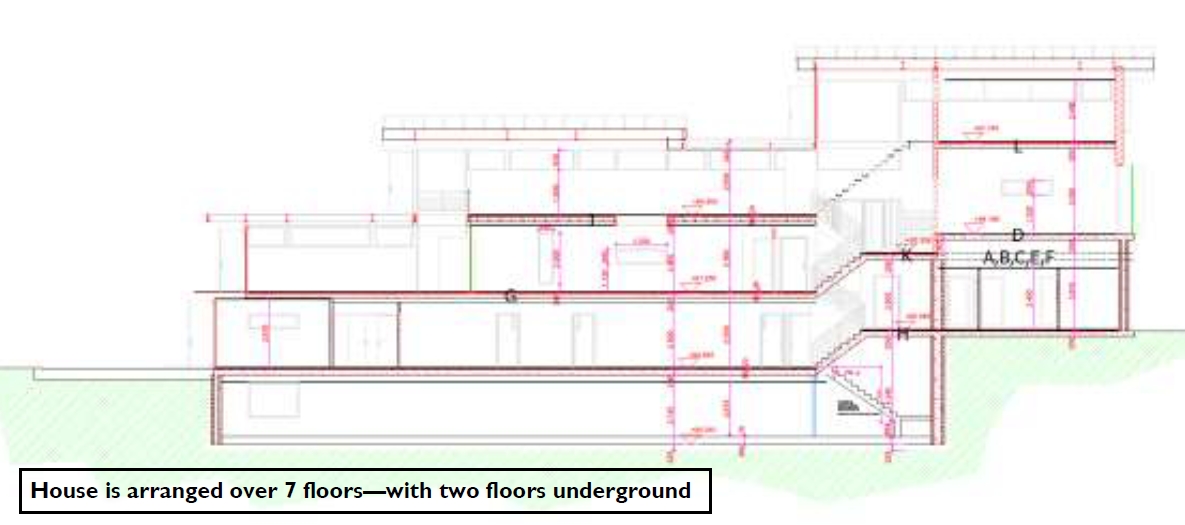

House is arranged over 7 floors—with two floors underground

House is arranged over 7 floors—with two floors underground