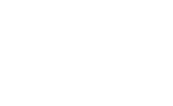

Konark Hospitals in Jeedimetla, India

Konark Hospitals in Jeedimetla, Hyderabad produces a daily wastewater volume of 13,000 liters which was being released untreated into the municipal drain. In order to stop the release of untreated sewage and achieve PCB compliance, an Aquatron® solid-liquid separator along with a simple water treatment plant and ozonator were installed at the hospital on September 3rd 2019.

The Aquatron® unit completely removes faecal solids from wastewater and thereby enables straight-forward treatment of separated flushing water and other grey water. The total project cost was about Rs 6.2 lakhs and the monthly operating cost works out to about Rs 5,000. This includes all media refills for the filters as well as all power consumption for the ozonator and one pump. There are no separate operator charges. The test results for outlet water from Konark’s Aquatron®-based STP are within the PCB parameter limits.

The hospital building along with all plumbing were at least 10 years old so Aquatron® had to be

retrofitted and an underground space had to be created to house the required tanks.

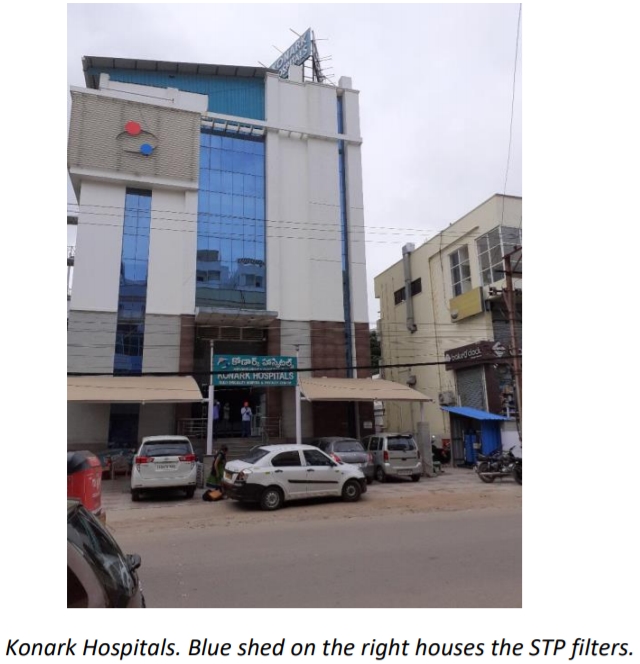

As the first step, toilet locations and the existing pipe layout were analyzed and the optimal way to

connect the toilets to Aquatron® was decided. Dimensions of the composting chamber and settling tank

were determined according to daily usage data received from the hospital.

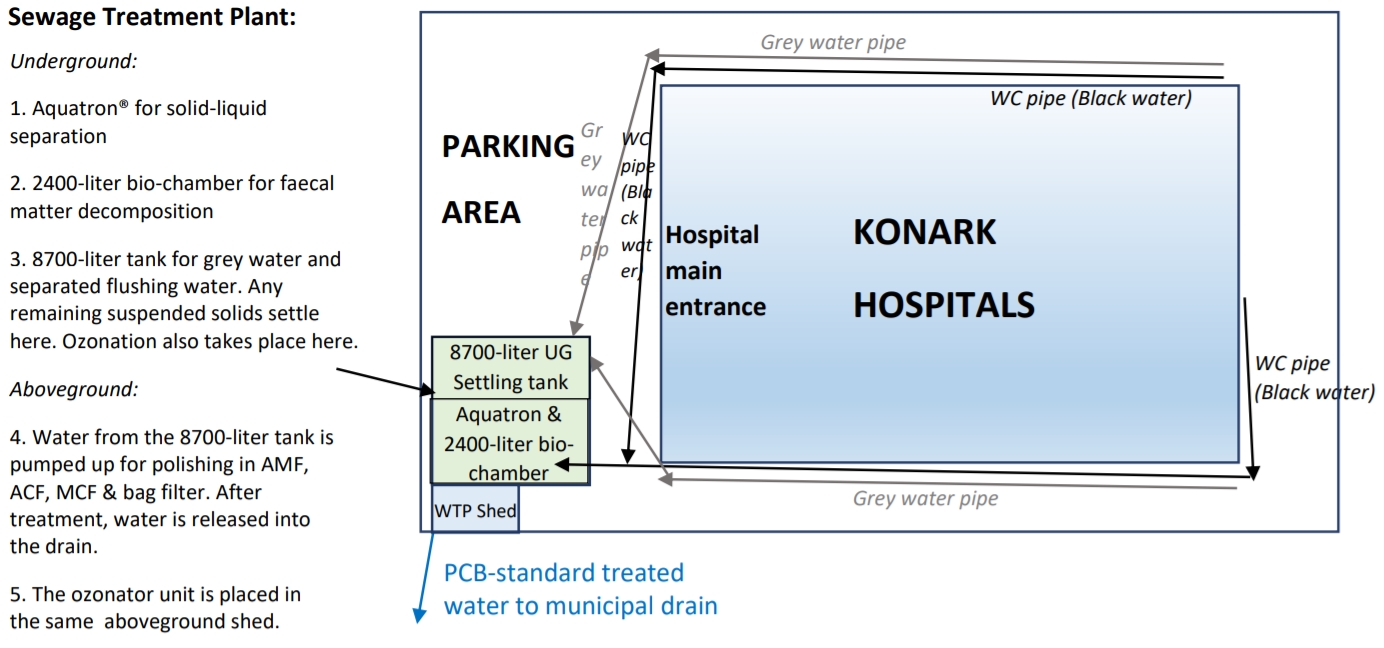

All 19 toilets in the property are now connected to a single Aquatron® unit which separates faecal solids

for natural decomposition in a 2400-liter bio-chamber. The bio-chamber was dimensioned for up to 100

residential users.

Under the bio-chamber, there is an 8700-liter settling tank (see diagram on previous page), consisting of

three compartments separated by baffle walls. The settling tank is used to collect all grey water as well

as separated water from Aquatron®. Ozonation takes place in the last compartment of the settling tank.

After ozonation, the water is further polished with an AMF, ACF, MCF and bag filter.

The execution had three phases: Underground space and tank construction, plumbing work and water

treatment plant installation (together with the protective shed).

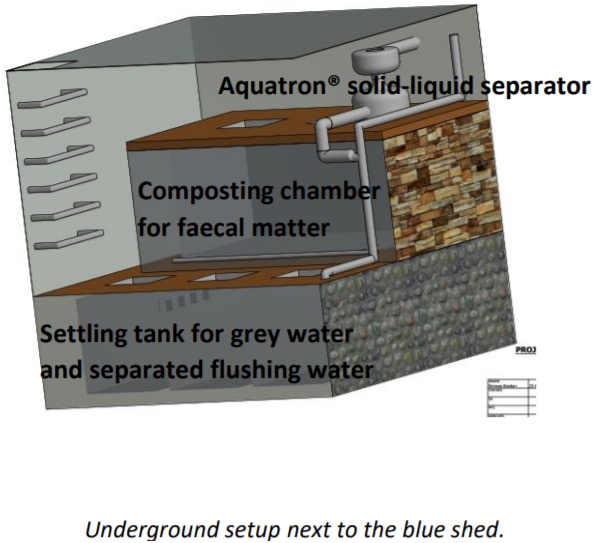

Underground space and tanks

The 3m x 3m x 3m underground room together with all tanks, plastering, waterproofing and slabs took

about 15 working days to complete for one mason and two helpers. This is excluding the curing time for

the top slab. The below series of images should illustrate the construction process.

Plumbing

Modifications to existing plumbing and new plumbing took totally 30 working days to complete. This

mainly involved diversion of the existing WC downtakes to Aquatron, creating new grey water lines,

connections from the settling tank to the water treatment plant and pipework within the water

treatment plant. There was an existing underground pipe with manholes leading out to the municipal

drain so instead of letting the downtakes enter that, the relevant pipes were cut and a new pipe without

manholes was drawn along the wall.

Installation of Water Treatment Plant and Ozonator

To complement the removal of faecal matter by Aquatron® and provide a sufficient treated water for

latest NGT standard, a water treatment plant with an activated media filter, activated carbon filter, bag

filter, micron cartridge filter, ultrafiltration plant and UV was installed at first. However, the UF plant

was unable to cope with the heavy chemical and biological demand of the hospital. As a measure to

provide a permanent, problem-free solution, a 5mg ozonator was installed and the UF setup was

removed.

Project costs

The total cost for the client came up to approximately Rs 6 lakhs, out of which Rs 2 lakhs was civil work

and Rs 4 lakhs was for equipment, plumbing etc. miscellaneous costs.

The CAPEX cost for the entire project is about 70% of the cost of conventional MBBR STP equipment for

a similar site. MBBR technology requires larger tanks for aeration as well as for collection of sludge and

treated water, which imply a higher cost of civil work. Apart from this, conventional systems need

frequent equipment maintenance and repairs and often a specialist operator too.

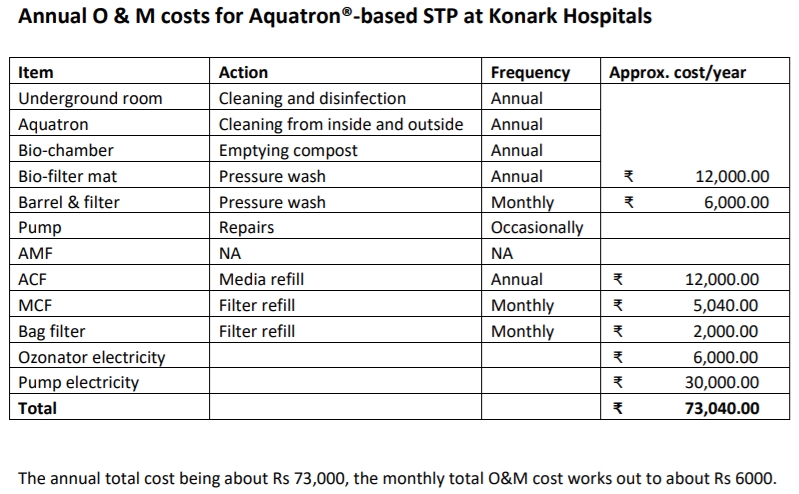

In regard to the operating costs, the monthly power bill for the Aquatron®-based system is about Rs

3000 which covers both the ozone generator and the pump. Other operating expenses consist of ACF

media replacement at an annual cost of Rs 12,000, 12 MCF filter replacements at an annual cost of Rs

5000 and bag filter refills at an annual cost of Rs 2000. Taking into account occasional cleaning of the

underground space, the total monthly maintenance cost works out to Rs 3000 or so

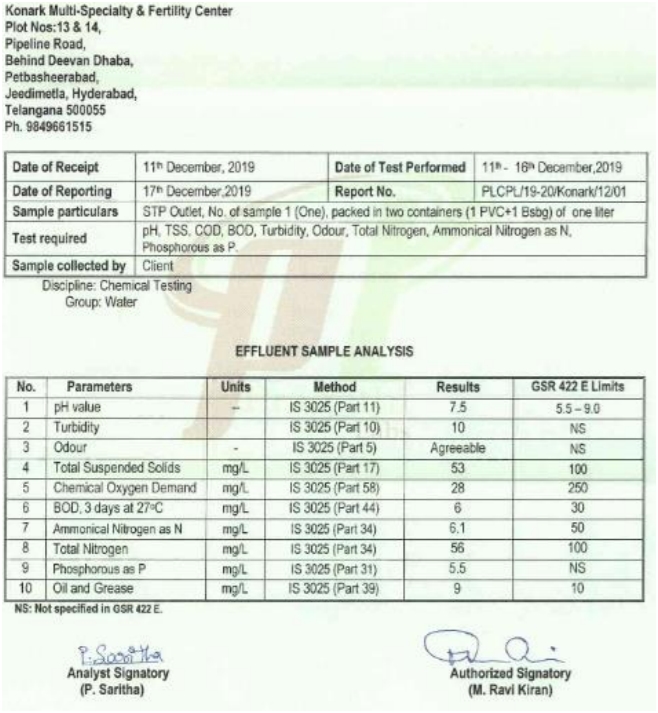

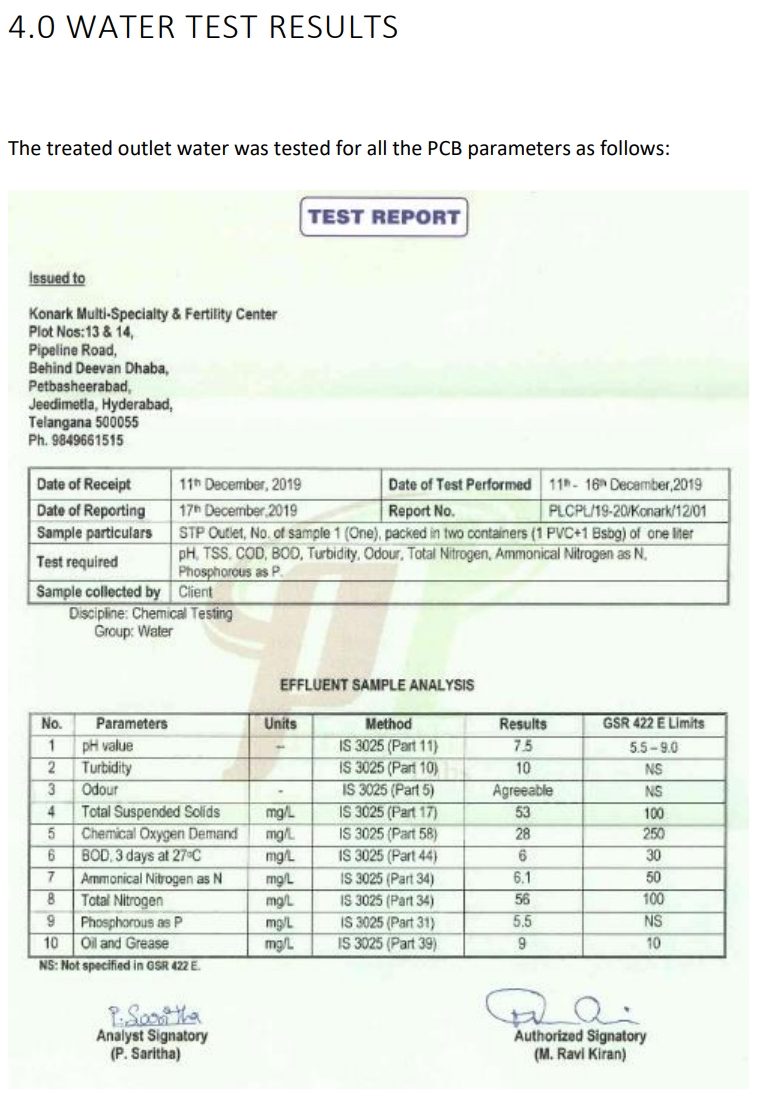

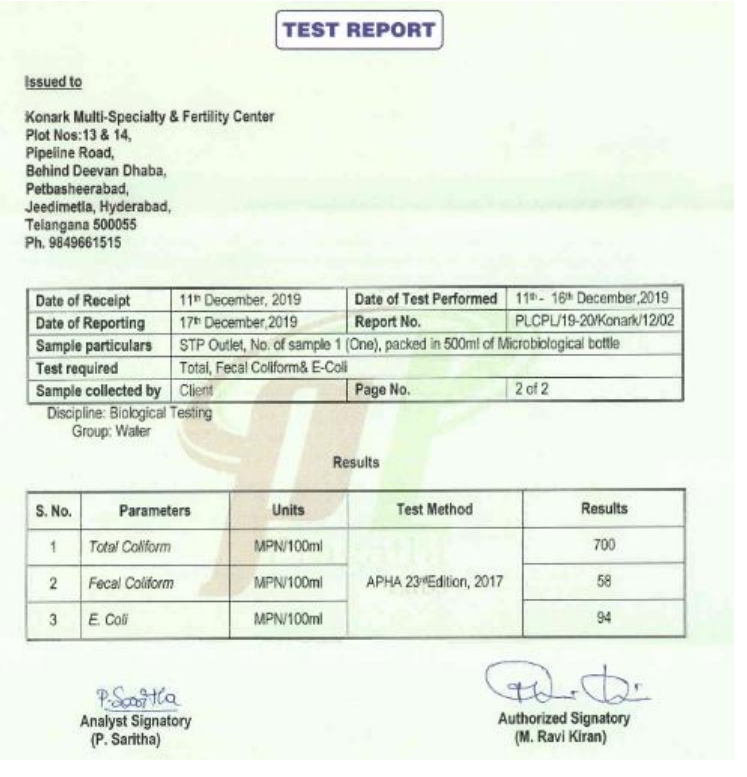

Water test results

The treated outlet water was tested for all the PCB parameters as follows:

SUMMARY

The Aquatron®-based sewage treatment system at Konark Hospitals was commissioned on September 3 rd 2019 in order to achieve PCB compliance and put an end to releasing 13 KL of untreated wastewater into the public drain every day. The Aquatron® separator eliminates the need to treat faecal solids by separating them from wastewater for direct, natural decomposition. Hence, the entire wastewater

(separated flushing water and grey water) can be treated by using only an ozonator, AMF and ACF instead of a much heavier conventional STP setup. By the date of this report, about 4 months from commissioning, the decomposition of faecal matter has been as expected and the filtration process has yielded the required water quality as evidenced by the lab test certificates.

The project took a total of 15 days of civil work, 30 days of plumbing work and 5 days of WTP installation work to complete.

Both the capital expenditure as well as operational expenditure were lower than for a conventional STP of a similar capacity: the system cost Rs 6 lakhs including all civil, labour and materials whereas the cost of a conventional STP would be in excess of Rs 10 lakhs. The total monthly operating cost for the Aquatron®-based system is about Rs 6000 which is less than half of what it would cost to operate a

regular STP.

Download full case study here:

Info

CountryIndia

Installed2019

More images

WATER TEST RESULTS

WATER TEST RESULTS

WATER TEST RESULTS

WATER TEST RESULTS