Admerus Biosciences, site-built solution

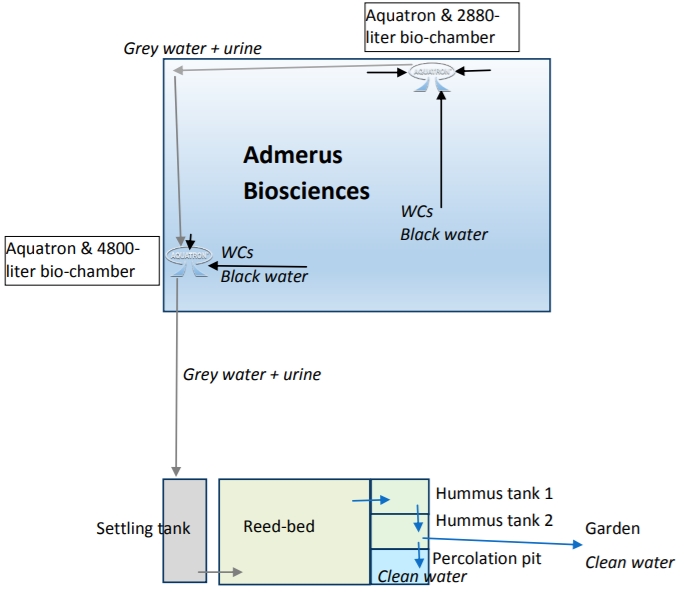

Admerus Biosciences is a clinical research facility near Hyderabad, India. The facility hosts 200 research volunteers and some 50 members of staff who are using 36 toilets connected to two Aquatron separators. The two bio-chambers at Admerus were built onsite and separated flushing water is treated together with grey water in a reed-bed. This system has been in use since November 2018.

The building was already under construction when Aquatron® was added to the plan but plumbing or STP-related work hadn’t been started yet.

As the first step, toilet locations were identified and the optimal way to connect the toilets to Aquatron® was decided. The dimensions of the bio-chambers and depths of underground pipes were determined and a reed-bed design was also drafted.

The bio-chamber on the west side of the building serves 15 toilets and usage is expected to be light to moderate in this part of the building. The chamber volume is 2880 liters.

The bio-chamber on the south side of the building serves 19 toilets and usage is expected to be high since it serves the volunteer accommodation area. The chamber volume is 4800 liters.

The Aquatron®-based STP at Admerus Biosciences research facility in Hyderabad was commissioned in October 2018. The system is based on two Aquatron® solid-liquid separators that stop faecal matter from mixing with the rest of the wastewater. In effect, this enables easy and cost-effective natural water treatment in a reed-bed and also allows the facility to reuse the wastewater for gardening or groundwater recharge through a percolation pit. The daily treatment capacity is 21 KLD and the eventual number of users will be about 250. The total cost for materials, construction and project management was about Rs 8 lakhs and the operating cost is limited to running a simple pump for about Rs 500 per month.

Execution

The execution had three phases: Bio-chamber construction, plumbing work and reed-bed construction.

Bio-chambers

Each bio-chamber, including the protective structure for Aquatron®, took about two weeks to complete

with one mason and two labourers.

Plumbing

Plumbing work for Aquatron® took approximately one man day to complete. It should be noted that

plumbing was done by connecting all WCs to closed-circuit lines without manholes. Most of the pipes

run along the basement ceiling and any bends used (horizontal and vertical) were 45 degrees.

Settling tank, reed-bed, hummus tanks and percolation pit

The settling tank, reed-bed, two hummus tanks and percolation pit took approximately 21 man days to

complete

Overview of the system

The Aquatron®-based sewage treatment system at Admerus Biosciences was commissioned on October 18th 2018. In essence, the Aquatron® separator removes the need to treat faecal solids by separating them from wastewater for direct decomposition. Hence, the entire wastewater of the facility can be directed to a reed-bed for easy, cost-effective and natural treatment.

The project took a total of 35 days of civil work and 1 day of plumbing work to complete.

Both the capital expenditure as well as operational expenditure are much lower than for a regular STP: the system cost about Rs 8 lakhs including all labour and materials and the monthly operating cost for the Aquatron®-based system is about Rs 500 which is a fraction of the Rs 20,000 electricity cost of a regular STP, which also has its AMC and occasional breakdown repair costs.

The new sewage treatment system ensures that the treated water from Admerus Biosciences is reused in a gainful way as well: it is mainly used for landscaping and a percolation pit for groundwater recharge has been provided too.+

COSTS

The total cost to the client came up to approximately Rs 8 lakhs.

The CAPEX cost for the entire project is less than 50% of the set-up cost for a conventional MBBR STP of similar capacity. In addition, MBBR technology requires large tanks for aeration as well as for collection of sludge and treated water, which imply a high space requirement, higher cost of civil work and other repair and maintenance work.

The monthly operating cost for the Aquatron®-based system is a current bill of about Rs 500 which is primarily for pumping treated water for reuse in the garden. This is a fraction of the Rs 20,000 monthly electricity cost + AMC and Breakdown costs to run a similar 21 KLD STP unit.

SUMMARY

The Aquatron®-based sewage treatment system at Admerus Biosciences was commissioned on October 18th 2018. In essence, the Aquatron® separator removes the need to treat faecal solids by separating them from wastewater for direct decomposition. Hence, the entire wastewater of the facility can be directed to a reed-bed for easy, cost-effective and natural treatment.

The project took a total of 35 days of civil work and 1 day of plumbing work to complete.

Both the capital expenditure as well as operational expenditure are much lower than for a regular STP: the system cost about Rs 8 lakhs including all labour and materials and the monthly operating cost for the Aquatron®-based system is about Rs 500 which is a fraction of the Rs 20,000 electricity cost of a regular STP, which also has its AMC and occasional breakdown repair costs.

The new sewage treatment system ensures that the treated water from Admerus Biosciences is reused in a gainful way as well: it is mainly used for landscaping and a percolation pit for groundwater recharge has been provided too.

Download full case study:

Info

CountryIndia

Installed20019